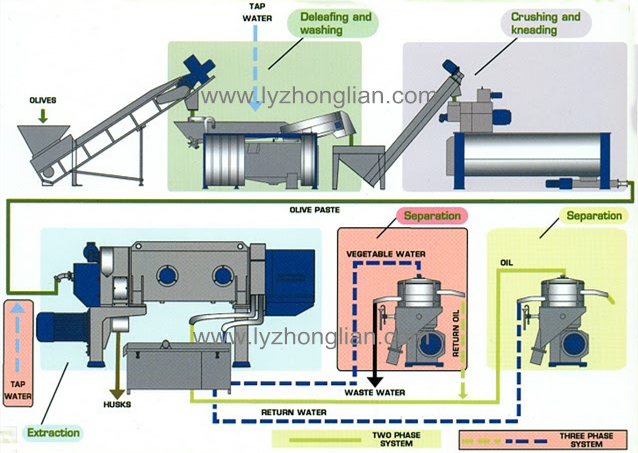

Liaoyang Zhonglian Pharmaceutical Machinery.,Ltd

Liaoyang Zhonglian Pharmaceutical Machinery Co., Ltd. was

established in 2001. The company is located in Liaoyang city,

Liaoning province and covers total area of seven thousand square

meters. The enterprise is specialized engaged in manufacturing and

selling pharmaceutical machinery. We have a professional technical

team and after-sales service team. The company have passed the ISO

9 0 0 1 Quality Management System Certification, CE Product

Certification and obtained many Utility Model Patent Certification.

At present, the products have been widely used in pharmaceutical,

chemical, food, mining, textile, environment protection and many

other industries. Through the unremitting efforts of all the staff,

the company has formed its own sales network all over the world.

The products have been exported to the United States, Greece, New

Zealand, Australia, Canada, Venezuela, Peru, Russia, Singapore,

Turkey, Japan, Korea, Thailand, Malaysia, Indonesia, Kenya,

Seychelles and other countries. The staffs are committed to provide

different solutions according to different users and different

requirements. With reliable quality and after-sales service, the

company won the support and praise of the broad masses of overseas

customers. In recent years, the company has built a long-term and

stable cooperation relationship with many strong manufacturing

enterprises in China.